As a soap maker, one of the biggest problems making a batch of cold process soap can be soda ash!

There’s a lot of advice out there on ways to remove soda ash, but very few helpful instructions on preventing soda ash on cold process soap. Preventing soda ash on cold process soap is very simple, once you know the secret!

You have probably heard that soda ash gives your soap a nice rustic look, or is easy to remove with water or steam. That’s great if you love that rustic look or have lots of extra time to nit-pick your soap to death. It sure doesn’t work very well if you want your vibrant soap colors and designs to pop! Or maybe you don’t want to be stuck making old fashioned looking soap for the rest of your soapy life. Besides that, anyone who values their time and money can’t spend hours cleaning up a mess that can be prevented in the first place. As a business owner there is no way this is a profitable option! Preventing soda ash is much easier and only takes a minute.

First of all, there are a number of things that can cause soda ash on top of cold process soap or even throughout the bar of soap.

Certain fragrance oils can be culprits and some additives can increase the odds of your soap batch developing soda ash. Be sure to read the reviews on the products you are using ahead of time! Additionally, soaping temperature and rate of saponification can affect the amount of white powdery topping on your bars. After all, making soap is part chemistry and part artistic expression.

With so many things that can cause soda ash on cold process soap, it can be hard to nail down what is actually causing it!

For me, most of my soap batches had soda ash. It was driving me crazy! I was covering, insulating, spraying the heck out of it with 99% isopropyl alcohol repeatedly and it was STILL showing up. Nothing I did helped!

After tons of research, and piecing tidbits of information together form other soap makers, I finally figured out what I could do in advance! It took me less than a minute, and has worked with every single batch of soap. One of THE most helpful blog posts, thanks to Clara is here.

The secret is in the water.

Sounds like a line out of a movie, but it’s true! The amount of water used when making cold process soap dramatically increases or decreases your chances of getting soda ash on top of your soap. That means the best way you will be preventing soda ash on cold process soap is to pay attention to the water!

For cold process soap, the more water you use, the more likely you are to get soda ash. I have found that a 30% or more water discount generally means I won’t see soda ash on my soap. The higher the water discount, the less likely the problem. I prefer to do anywhere from 35% to 45%. You never want to discount more than 50% of the water. Read more about using a water discount here.

Now, keep in mind that less water means that trace will happen faster. If you are using a recipe with a lot of hard oils it will reach trace faster. When you use a fragrance or essential oil that speeds up trace, like clove essential oil, it will reach trace faster. If you soap at higher temperatures, your soap will reach trace faster. So however your soap recipe behaves without a water discount, just keep in mind that water discounting will decrease trace time!

Ways to slow down trace time when using a water discount:

- Soap with your lye water solution and oils at room temperature

- Increase the percentage of oils in your recipe that slow down trace (avocado oil, olive oil, etc.)

- Stay away from essential oils and fragrances that accelerate the time it takes to reach trace

- Stick blend less

Another thing to remember is that the humidity where you are can also affect your soap. If you have high humidity (over 30%) on soap making day, consider a slightly higher water discount.

An additional point worth noting is, the more water you have in your batter plus the longer that water is exposed to air, the more likely it is that you will find soda ash on cold process soap. It seems that batches poured at a thinner trace (more watery consistency) take longer to go through the saponification process. A medium to thick trace helps speed things up a bit.

Just in case you’re using tap water for your soap, know that it’s been reported to be another cause of soda ash on soap. Find out more problems associated with using tap water in your soap here.

Once you adjust your recipe with this little tweak, you will be preventing soda ash on your cold process soap. You will be making colorful, intricate soap designs in no time without the help of the unwanted powder fairy. If this was helpful, please share! If you have questions, please leave a comment below. I would love to hear from you!

Fantastic. I have so much to learn. The link to auntie annie’s no colorant soap was very elucidating.

Hi, Brad! I’m glad you stopped by! The learning process is so much of the fun… well, most of the time anyway. There’s so much science and art involved, it would be very hard to get bored of it. 🙂

Can you reduce the water without altering the rest of the recipe?

Hey, Sarah! Yes and no. Let me explain.

First, you can safely reduce the amount of water without changing the amounts of the other ingredients.

Keep in mind; you can safely reduce the weight of your water to be a 50/50 ratio with the weight of your lye. For example, if your recipe calls for 4.2 ounces of lye, you can reduce the water down to 4.2 ounces and still be OK – mostly. I usually have issues when I reduce this far. It seems like the lye doesn’t completely dissolve in the water. The reason for this I think is because you get some evaporation of the water as it heats up. That reduces the water just a little too much. You have to have enough water to dissolve and absorb all of the lye. Because of this, I usually go with a little more water than the 50/50 ratio.

Now, when you reduce the water in your recipe, you may have your soap behave differently. Which is kind of the point, right? We don’t want it to “grow” soda ash. When you reduce water, your soap will begin to reach the trace stage FASTER. Plus, it will also be harder to get it to go completely through gel phase if that’s what you want your soap to do for brighter colors.

If you have a recipe that already reaches trace pretty fast, or you are using any additives that speed up trace, you may find yourself with a very fast-thickening soap. What I would do is experiment and reduce the water in your recipe until you get to the point you no longer are getting ash. If that doesn’t work, it’s probably some buggar ingredient you are using that is causing the soda ash.

Thanks so much for replying! I’m a beginner soaper and it’s so disappointing when they don’t turn out how you’d like.

You are welcome, Sarah! I know what you mean about the disappointment. It does get easier as you go, though. Even experienced soap makers have failed batches sometimes… It just goes with the territory. But, keep trying! It really does get easier with practice.

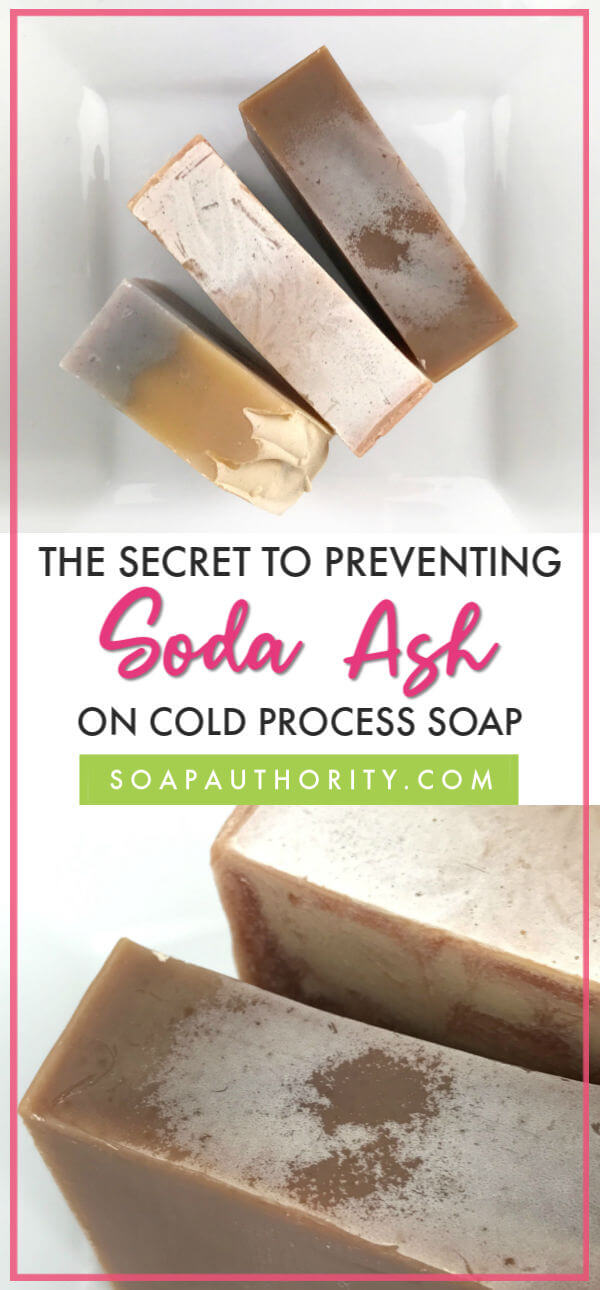

The middle bar in your main picture looks like my last couple of batches. Is it normal to have to use a peeler to get soda ash off on the top? Is the type in that pic embedded in the top layer or powdery and steams off?

I tried steaming it but its not powdery it almost seems embedded in the top layer. So peeling takes it off but then I can’t do a fancier design if I have to use a peeler.

Hi, Erin! I totally understand your frustration! I’ve had some beautiful batches of soap taken over by that annoying soda ash. The bar in the middle of the picture is a thicker layer of soda ash and is harder to steam off because there is more of it. Steam can help a little with that, but it will never get all of it. It is normal to have to use a peeler or a soap planer to get that thicker layer off. The bar of soap on the left side is the one that would see the best results from steaming.

Soda ash can be on top of the bar or embedded in the top layer. I’ve even had it throughout the middle of the bar depending on the additives – yikes! If you want to do fancier designs that don’t get soda ash, they key is finding a recipe that won’t create the ash. You have to be able to reduce the water in your recipe enough to get it to go away. The problem is, the less water you have, the faster your soap is going to thicken before you pour. To combat this, using a recipe with a larger amount of a slow tracing oil, like olive oil, will help slow things down.

Keep in mind, some fragrances make the soap get soda ash no matter what. Lavender is one of them. You might experiment with small unscented batches until you get a recipe that works well and go from there.

Hi Jaimie

Can you please tell me which soap calc do you use?

I usually use soapcal.net and for my last soap ( iwhich i had soda ash problems grrrrrr) i used the one onhttps://www.brambleberry.com

i have noticed that for the same recipe both calc use very different amounts of water.

can you tell me what amount of water would you use for this recipe?

olive oil 430gr

castor oil 30gr

coconut oil 140gr

so its a 600gr total oils

for this recipe i used 187 gr of water

i noticed that trace was very fast, maybe 1 or 2 minutes with the blender

thank you so much for your help

Hi, Paulo! I use Soapmaker 3 software, but you don’t need that to figure out how much water to use. Each calculator programs in their own standard amount for water and that’s why you are seeing different results. Assuming the recipe you gave me has a typical superfat of 5%, that’s 84g of lye.

Your lye solution strength with 84g of lye and 187g of water is about 31% ,which is pretty standard. To calculate your own water amount based on the lye solution strength you prefer, here’s the formula. I’ll start with the 84g of lye and the 31% lye solution strength so you can see where the water amount you gave me came from.

Formula:

(Lye weight/Desired Lye Solution Strength) X (100% – Desired Lye Solution Strength) = Water Weight

(84/31 )X (100-31) = Water Weight

2.7097 X 69 = 186.97g Water

See? That math checks what you gave me. Now, to reduce or eliminate soda ash, I would start with a 35% lye solution strength. Let’s see how much water that would be assuming you are using 84g of lye.

(84/35) X (100-35) = Water Weight

2.4 X 65 = 156 g Water

So, the short answer is to reduce the water you use to 156g, which is a 35% lye solution strength. If that doesn’t work, you can increase the lye solution strength to 37%. Never go above 50%. Also, make sure to cover your soap to limit air exposure during the 24 hour period right after pouring.

If you are worried about it tracing faster since you are using less water, stick blend less, and soap at lower temperatures.

For more information on lye solution strength, Kenna from Modern Soapmaking has a great post that goes into detail about it here.

Thank you so much for your help

I will try it again today…never give up 🙂

warm smile from Portugal

You are welcome! I hope it works out for you sooner rather than later! 🙂

Jaimie,

It came out simply BEAUTIFUL! thank you so much

warm smile from Portugal

That’s great, Paulo! I’m so happy that it worked out for you. 🤗 Thanks for taking the time to post an update!

Im so glad to see people are getting results!

Quick question Jaimie, does it matter how much water discount by specifics or lets say for a small batch 40oz loaf, it asks for 7.05oz of water. Would it work if i discount an entire oz of water or does it have to be a specific amount of water?

Thanks again!

Hi, Adrine! Great question! It doesn’t have to be a specific amount. Sometimes it’s easier to adjust the water by small, rounded increments to make it easier. You could definitely start by decreasing the water by 1 oz, then maybe 1/2 ounce more if needed until you are not getting any soda ash. Just make sure you never ever decrease your water amount to less than the weight of lye you are using. For example, if your recipe calls for 2 oz of lye by weight, make sure you use at least 2 oz of water by weight. That is the minimum 50/50 ratio needed for the lye to completely dissolve in the water. For me, I always use a little more water than the weight of the lye, because I’ve had problems with it not dissolving completely when I cut it too close. Undissolved lye can leave lye specks in your soap, which can burn the skin.

Hi Jaimie,

I got frustrated with soda ash in the middle of my soap.

Fyi, I used kaolin clay in this batch, and it causes crack on top of my soap.

This is my first time adding kaolin clay and my first time

also getting crack on top of it.

Is it possible that the crack on top causes air to go through the middle of the soap and causes soda ash? Or the kaolin clay itself could cause soda ash?

I hope this makes sense.

Thank you in advance!

Hi, Erika!

I have never had any issues when using kaolin clay in soap, except it does speed up trace a little bit. I use up to 3 Tbsp in 50 ounces of soap. (That’s about 11 – 4.5 ounce bars.) Cracking is usually caused by your soap overheating. I have found that soda ash in the middle of the soap is usually caused by the fragrance oil or essential oils used. Without knowing the amount of kaolin clay used, the recipe and any other additives, it’s really hard to tell what caused the crack and the soda ash. If you are comfortable sharing more details, it would better help narrow down what went wrong.

Hi Jaimie, thank you for this article however I’m still having huge problems with soda ash. I unmoulded a peacock swirl today and there was ash on every surface except for an area in the centre of the bottom surface! I haven’t cut it yet so don’t know how invasive it is.

I now use a standard 38% lye solution. After the pour I covered the mould with cardboard and put it in a foil insulated pouch. I didn’t disturb it for 48 hours.

It seems to me that the more liquid the batter, the worse the soda ash. So most of my problems are with swirl designs. If I do a design with embeds which requires a thicker batter to stop the embeds sinking, I don’t seem to get such a problem.

I’ve tried putting the moulds in the airing cupboard and in the fridge and don’t get any noticeable difference. Spraying with isopropyl alcohol or covering with cling film, still doesn’t stop it. I’ve used a number of different fragrances and don’t seem to be able to blame it on that. I haven’t yet tried c-popping in the oven. Could it be as simple as the thickness of the batter? Does that mean I’ll have to give up swirls? I don’t understand why it happens to me and not other people. Any suggestions gratefully received.

Kind regards.

Hi, Christine! I feel your pain! To have such a beautiful work of art ruined after the fact is extremely frustrating. Slow trace recipes are wonderful for detail work, but the worst for soda ash. Fluid batter is always exposed to air longer because we work with it longer and it takes longer to saponify once in the mold. Basically, the thicker we get our soap before pouring, the more we have moved it along in the saponification process, so it cuts down on the time exposed to the air.

The big clue is where you did not have soda ash – the most insulated, warmest part of the loaf. I would definitely try experimenting with CPOP to move saponification along faster and lessen the soda ash. Plus, it will give you more beautiful rich colors with your peacock swirls!

Since you already have such a large water discount and still have a fluid enough batter, I would look at increasing the superfat percentage and soaping at warmer temperatures.

Hi Jaimie!

Great article – I was wondering if you could give me a little insight on my problem here:

I’ve been slowly reducing the amount of water I use to combat the dreaded soda ash – I’m down to 1.7:1 water:lye and I’m still getting ash. The reduced water also makes it much more difficult to get any gelling happening in my soaps, even when CPOPing!

Any advice? Thanks in advance!

Hi, Julian!

It sounds like the water is not the problem. Not knowing anything else about your recipe, I would wonder if you live in a humid region. Another possibility is the recipe you are using. One or more of the ingredients could be the problem. Yes, with CPOP you do need more water to create more heat for your soap to gel. That’s the never ending battle with soap. We are always sacrificing one thing for another hoping we can find that “sweet spot” where we get most, if not all, of the desired outcomes. I would suggest trying different recipes or substituting ingredients and doing some detective work until you find the culprit. The process of elimination will help. Just make sure to only change one variable at a time.

I hope you can get it figured out! I know how frustrating all this can be. 🙂

THANK YOU!

I really needed thos knowledge, thanks for sharing and not keeping it to yourself.

I will implement this right away and se if the powder disappers.

Warm greeting from The Faroe Islands

You are welcome, Katja! I hope your soap turns out beautiful!

Hi! I just recently been having trouble with ash! I usually I an okay. But I was soaping with a grapefruit and lemon grass EO and I got a thick layer of ash! Like, I can scrape it off with my thumbnail.

I made this batch before with only a little ash, but not this bad. I usually soap at quite a low temp though.

Do you know if grapwfruit and lemongrass are more apt to cause ash??

Thanks!!!

Hi, Tyler! I haven’t had any problems with them, but not all essential oils are the same. There are differences with distributors and their sources, and essential oils can vary from batch to batch depending on growing conditions of the plants they came from. If you have made batches before with little ash previously, it might be another variable causing your ash.

I sprayed 90% isopropyl alcohol on the top of my soap and still got a layer of ash! Some spots were ok, but most of it was ashy. Did I overspray in some spots? This was a large batch so maybe I need to reduce the amount of water.

Hi, Deborah! I have never had any luck with isopropyl alcohol preventing ash. Maybe it helps evaporate any moisture on top of the soap a little quicker, but not for me. Yes, do try and tweak the water amount to see if that helps. Sometimes the humidity in the air can contribute as well, so I always make sure to cover my soap well while it sits in the mold that first day. Another thing to try is getting some 99% isopropyl alcohol instead, because when you use one that’s 90%, the other 10% is water.

Hello

Thank you for wonderful information! Could you describe how fo you add kaoline?

Hi, Fanny! You are welcome! I like to mix my kaolin clay with the fragrance portion of my recipe to help anchor the fragrance in the soap. Another way to do it, is to mix it in some or all of the oils before you add in your lye solution. The kaolin clay does like to absorb water, so it will speed up trace a little bit even if you mix it with the oils or fragrance first. You could add it at thin trace if you want. It just might be harder to get it evenly mixed before the soap thickens too much if you have a recipe that reaches thick trace faster than average.

Hi Jaimie! I have had the same issue you described! My water is currently at “35% of oil weight” on my soapcalc.com recipes. When you say to discount the water 35-45%, does that mean reduce my 35% by 35%? Just making sure I understand… 🙂

Hi, Christine! That is such a great question! This topic can be confusing, especially since the soap calculators out there calculate water either 1) based on a percentage of the oil weight, or 2) based on the percentage of lye weight. I always use lye weight. In my opinion, using the oil weight to calculate water is flawed.

The types of oils with their SAP Values, the weight of oils and desired superfat percentage determine how much lye you will need for your recipe.

Once you know how much lye you need, then water can be determined. So, when I said to do a water discount of 35-45%, what that means is 35-45% of the lye solution is the lye crystals and 65-55% of the lye solution is the water, by weight. (35% lye + 65% water = 100% of solution)

The percentage of the lye in the water is called the lye solution strength. The lower the percentage of the lye, the weaker the solution. The higher it is, the stronger or more potent. Since we don’t have the option to change the amount of lye we need to correctly saponify our oils, to make our lye solution stronger, we must reduce the water. That’s why it’s called a water discount.

Once you pick the lye solution strength you want, here is the formula to calculate how much water you will add:

Lye weight / desired lye solution strength x (100% – Desired Lye Solution Strength) = water weight to use

Let’s say the lye needed for my recipe is 4.45 ounces and I want that 35% lye solution strength that seems to work at preventing most soda ash. It would look like this:

4.45 / 35% x (100% – 35%) = .12714 x 65 = 8.26 ounces of water

If that seems too confusing, here’s the quick and dirty trick:

Whatever your weight of lye is for your recipe, your water has to be the same weight or MORE! Keep your water weight between the lye weight and the soap calculator weight. So start reducing your water by a half ounce at a time until you don’t get soda ash, making sure you never have less water weight than lye weight.

For example, my recipe needs 4.45 ounces of lye and the soap calculator is saying to use 12.9 ounces of water. I must use at least 4.45 ounces of water but I can use anything less than 12.9 ounces of water.

Wow. Thank you so much! I’m on it! And that makes total sense. Thanks for explaining so well!

You are very welcome, Christine! I’m glad it makes sense. BTW… love your cute little goats!

That is an excellent explanation! Thank you!!

Thank you. When talking about using less water ie 30% & you usually use 35-45% what section is that in soapcalc.com where I’d add the 35%?

1. Water as % of oils

2. Lye concentration or

3. Water : lye ratio

I usually use the water as % of oils but been reading about 50/50 lye concentration to speed up cure and now seeing this post after I was searching how to prevent soda ash.

Hi, Stephanie! On soapcalc.com under the water section you would select “lye concentration” and in that box put your water discount number. For example, if I wanted a 40% water discount, I would type in 40.0 in that box. If I wanted a 35.8% water discount, I would type 35.8 in that box. While you can use water as a percentage of oils, I don’t think it’s the best method. This is why…

Your water amount is DIRECTLY tied to your lye amount, your water amount is INDIRECTLY tied to your oils. That means that oils determine lye, lye determines water. Your oils don’t determine water.

Good evening. Texting from Cameroon. Am happy going through the advice. The question an answer. I do use palm red oil. To do soap. I don’t know if its also one of the problems bringing soda ash. I leave in cold temperate zone. Please i need help

Hi, Ngala! I haven’t personally used red palm oil, so I can’t say for sure if it causes problems with soda ash, but regular palm oil doesn’t seem give me a problem. If you have already tried lowering the water amount, you could try a different type of palm oil, since it has the same SAP value. Another thing you could do is try beef tallow if that’s something you have access to. It has a nearly identical SAP value to palm oil, meaning you can swap it out in your recipe without having to change the amount of lye you are using. You could test your regular recipe in a batch alongside a second batch that has the substitute, keeping everything else the same. That should help you troubleshoot if its specifically the red palm oil giving you the issues with soda ash.

Thank you very much for your advice. I had the ash problem.

Water reduction in soda ash solution is well noted. Alex from Uganda